Corporate

Corporate

GBL Bets On Biochemicals While Ethanol Acts As Safety Net

businessworld.in | Sep 01, 2025Executive Director Sangeeta Srivastava says that ethanol remains a safety net as the company expands feedstock flexibility and bio-based product portfolio

Godavari Biorefineries (GBL) is betting big on bio-based chemicals as the next growth engine, with plans to triple its earnings before interest, taxes, depreciation, and amortisation (EBITDA) between FY25 and FY29. Executive Director Sangeeta Srivastava said the company sees ethanol as a stabilising pillar under India’ s blending programme but is directing future capital towards biochemicals to align with global decarbonisation trends

“ We believe ethanol gives us financial and operational security, but our growth will come from biochemicals, ” Srivastava told BW Businessworld in an interview. “ We maintain only a minimum balance in sugar, while ethanol provides stability. Chemicals are where the real growth lies.”

Ethanol As Safety Net, Biochemicals As Growth Driver

GBL operates across sugar, power, chemicals, and distillery segments. Its capital deployment, Srivastava said, is now guided by a philosophy that prioritises ethanol as a buffer and chemicals as a long-term value creator. “ We aim to decarbonise the chemical value chain through co-creation with customers, bringing in bio-based carbon for drop-in molecules, ” she noted.

With India’ s ethanol blending target recently raised to 30 per cent, GBL continues to supply about 85– 90 per cent of its ethanol to the programme. But the company has been diversifying uses, reducing dependence on the policy while supporting energy security and farmer incomes.

To enhance operational resilience, Srivastav said that GBL is investing Rs 130 crore in a new 200 KLPD grain- and maize-based ethanol facility. This will supplement sugarcane-based operations and extend plant utilisation beyond the traditional crushing season.

“ Sugarcane operations typically run for 130– 140 days, but with grain feedstock we can operate longer, ensuring better asset utilisation, ” Srivastava said. “ Availability of corn in the same region protects us from supply disruptions, while flexibility allows us to integrate multiple feedstocks smoothly.”

This move, she added, will not only help meet government blending targets but also shield operations from climate and seasonal risks.

Strengthening Farmer Partnerships

GBL’ s growth strategy also hinges on securing sustainable feedstock through deep engagement with farmers. The company established an independent Agricultural Research Institute at Sameerwadi, Karnataka, which works with scientists and cultivators to improve cane varieties, soil fertility, and crop resilience.

“ Our journey began with farm-level innovation to enhance soil health and continues today with collaborations with institutions like Somaiya Vidyavihar University and Michigan State University, ” Srivastava said. “ We are adopting both traditional practices, such as Panchagavya and modern scientific methods to retain soil carbon.”

She said that GBL is positioning itself as an import-substitution player in bio-based chemicals. One recent success is the commercialisation of Ethyl Vinyl Ether - previously fully imported into India and largely fossil-based. “ We developed and scaled this bio-based product in-house, ensuring it met customer specifications. It has now been approved by Indian buyers and international partners, ” she added.

Looking ahead, the company is targeting bio-butanol as a major growth molecule. “ We have communicated to investors that from FY25 to FY29, we aim to achieve 3 times EBITDA, with bio-butanol playing a significant role, ” she added.

ESG And Sustainability Priorities

“ All our facilities are zero-liquid-discharge, with 84 per cent of our energy coming from biomass and nearly all water recycled, ” she noted. “ We run schools in factory areas, train local communities, and ensure environmental awareness. ESG is not just a compliance requirement but part of how we create value.”

On the future of India’ s biochemical sector, Srivastava said the global shift towards decarbonisation has opened a window of opportunity for Indian producers. “ India has abundant biomass and the capability to convert it into products. If supported with the right incentives, we can be a global supplier of green carbon, ” she said.

She stressed that the world is looking for fossil replacements. The growth potential is enormous, and India can play a much bigger role in embedding bio-based carbon into global value chains.

Source: businessworld.in

Godavari Biorefineries drives innovation in renewable materials

businessindia.co | Jul 10, 2025

GBL is a producer of ethanol and a pioneer in ethanol-based chemical manufacturing in India

Looking at the increase in the biochemicals market, GBL is invested in capacity and innovation

Today, the world is seeking greener and renewable feedstocks in its search for sustainability. India holds immense potential in the biochemicals and renewable materials space, largely due to the country’s rich agricultural resources and the increasing need for sustainable solutions. With the growing demand, as well as investments in capacity and innovation, India is well-positioned to become a leader in this sector.

“We already have a presence in global supply chains, and with increasing investments in technology and innovation, we can take the lead in offering sustainable solutions. The focus on clean energy, environmental responsibility, and circularity in India is driving the industry forward, making India an attractive player in the global biochemicals market,” explains Dr Sangeeta Srivastava, ED at Godavari Biorefineries Limited (GBL).

With a PhD in organic chemistry and over 28 years of experience, she has been instrumental in driving innovation, sustainability, and ESG alignment at the company. A holder of 19 Indian patents and a respected voice in national industry forums, Srivastava brings a unique blend of scientific acumen and strategic leadership to the evolving landscape of biorefining.

“GBL offered me a valuable platform to explore the world of research while broadening my perspective beyond the laboratory. Although I joined as a technical officer, I was encouraged to engage with cross-functional teams and senior leadership, which deepened my understanding of how businesses operate holistically. At GBL, I learned that being hands-on is a critical trait of effective leadership. Equally important is taking ownership, of both success and failure, with passion and accountability,” she adds.

GBL is a producer of ethanol and a pioneer in ethanol-based chemical manufacturing in India. Its diversified product portfolio comprises bio-based chemicals, sugar, rectified spirits, ethanol, other grades of alcohol, and power. It is the only company in India to have such a vast portfolio of bio-based products such as MPO, natural 1,3 butylene glycol, ethyl vinyl ether, and other bio-based chemicals.

Financials speak

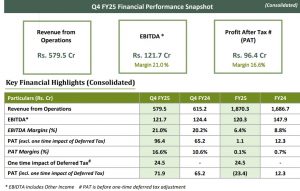

GBL recently declared its results. For Q4 FY25, with an operating profit (EBITDA) margin of 21 per cent and a profit after tax (PAT) margin of 16.6 per cent, reflecting operational efficiency and strategic execution, the company demonstrated a strong performance. In fact, the revenue from operations stood at Rs579.5 crore in Q4 FY25, compared to Rs615.2 crore in Q4 FY24. EBITDA was Rs121.7 crore, and PAT stood at Rs96.4 crore.

Speaking on the results, Samir Somaiya, CMD says: “FY25 was a defining year for GBL, showcasing our agility, disciplined execution, and strategic progress. Our bio-based chemicals segment delivered over two times growth in EBITDA, propelled by our shift towards high-value, sustainable solutions and enhanced operational efficiencies. We also achieved a record cane crushing of 24.65 lakh tonnes for sugar season 2024-25 at our Sameerwadi facility. The restoration of the ethanol blending programme using sugarcane juice enabled us to better utilise our ethanol capacity during the crushing season.”

Somaiya also serves as Chancellor of Somaiya Vidyavihar University, President of Somaiya Vidyavihar, and Chairman of Somaiya Trust and the KJ Somaiya Trust, among other roles. Over a career spanning close to 30 years, he has focused on a multitude of sectors from rural development and education to manufacturing. In 1993, he joined GBL and has taken the company forward through a focus on economic, social and environmental sustainability supported by research and innovation. Under his guidance, institutions under the Somaiya umbrella manage over 30 educational institutions, including the University.

Capital allocation

GBL has invested in capacity and innovation. But what guides this capital allocation and investment strategy? Says Srivastava: “Our capital allocation strategy at GBL is driven by two primary factors: sustainability and innovation. We are focused on enhancing our production capabilities and expanding into new product categories that align with global sustainability trends. Our investment strategy is also guided by the potential to create long-term value through co-creating with our customers. By integrating renewable materials into various industries – whether it’s for bio-based solvents, chemicals, or packaging – we aim to create scalable, sustainable solutions that meet both regulatory requirements and market demands.”

She adds: “For GBL, innovation starts at the farms where we generate our feedstock, gets created in the lab and takes shape with customers’ inputs. Such innovation, paired with smart capacity building, enables us to stay ahead of the curve and cater to emerging global needs.”

Meanwhile, the company has announced that its European patent for a novel anti-cancer molecule has been validated in Spain, the United Kingdom, and as a Unitary Patent covering multiple EU member states. This milestone underscores the company’s growing presence in high-impact scientific innovation, led by its dedicated Anti-Cancer Research segment.

The patented molecule has demonstrated efficacy against both cancer cells and cancer stem cells, marking a promising advance towards more targeted and effective cancer therapies. It has shown potential in the treatment of various cancers, including breast and prostate cancer, with encouraging efficacy and safety profiles in preclinical animal studies. The molecule is currently in Phase 1a clinical trials to assess safety in human patients with advanced solid tumours as well as in healthy volunteers.

“This patent validation marks a significant milestone in our journey towards advancing original, high-quality scientific research,” said Srivastava. “It reflects the dedication of our teams and our aspiration to contribute meaningfully to global knowledge and innovation,” she added.

GBL’s products are in sectors – pharma, cosmetics, food and fragrance, coatings – which are the key growth drivers for bio-based solutions. “We see strong momentum in several sectors, particularly in cosmetics, personal care, and pharmaceuticals,” says Somaiya. He sees the rising consumer awareness and regulatory shifts; these industries are increasingly prioritising sustainability and safety. 1,3 Butylene glycol, for instance, is already used in a wide range of personal care products, including skincare, haircare, and cosmetics. These are highly sensitive formulations where safety, stability, and efficacy are non-negotiable.

“We work closely with our clients in these sectors to provide bio-based ingredients that contribute to not just performance but also compliance and consumer trust. As global demand for clean-label and sustainable products grows, we see our solutions playing an increasingly strategic role,” discloses Srivastava.

As GBL moves forward, it is placing bold bets on advancing its bio-based product portfolio, with a focus on sustainable materials and new technologies such as microbial fermentation technologies and biotransformation. “We are also expanding our geographic reach to markets that are increasingly emphasising sustainable solutions, especially in Europe and North America. These regions have strong regulatory frameworks supporting the use of bio-based chemicals, and we are looking to increase our presence there,” explains Srivastava, exploring new verticals, particularly in advanced materials and sustainable agriculture. “By diversifying into new product categories, we aim to offer holistic solutions that not only cater to existing industries but also unlock entirely new markets for sustainable bio-based products.”

Now, the Government of India is promoting ethanol production as announced in the ‘Roadmap for Ethanol Blending’. This ethanol blending programme helps India meet its energy security, combat climate change, and ensure farmer incomes. In line with this policy, GBL expanded its ethanol capacity from 2 lakh litres per day to 4 lakh lpd. The company is now planning to increase capacity to 6 lakh lpd in the next few months. More than 40 per cent of the sugarcane feed to Godavari will be diverted to make ethanol.

“Looking ahead, our 200 KLPD grain/maize distillery is progressing as planned and is expected to be commissioned in Q4 FY26. We are also exploring multi-feedstock options for greater flexibility, while undertaking debottlenecking and expansion initiatives focused on specialty products. FY25 has laid a solid foundation for future growth, and we remain committed to delivering value through innovation, sustainability, and disciplined growth,” concludes Somaiya, a squash enthusiast, yoga practitioner, swimmer, and black belt in Taekwondo.

Source: businessindia.co

Godavari Biorefineries' patent for anticancer molecule validated in Spain, UK and EU

Jul 07, 2025

Godavari Biorefineries on Monday (July 7) announced that its European patent for a novel anti-cancer molecule has been successfully validated in Spain, the United Kingdom, and as a unitary patent across multiple European Union member states.

The patent validation marks a significant development in the company’s efforts within its anti-cancer research segment and strengthens its footprint in high-impact scientific innovation.

In a stock exchange filing, Godavari Biorefineries said that the patented molecule has demonstrated efficacy against both cancer cells and cancer stem cells and is being explored as a potential therapy for various cancers, including breast and prostate cancer.

Preclinical animal studies have shown promising results in terms of efficacy and safety, the company informed the bourses.

The molecule is currently undergoing Phase 1a clinical trials to evaluate its safety in patients with advanced solid tumours and healthy volunteers.

“This patent validation marks a significant milestone in our journey toward advancing original, high-quality scientific research,” said Sangeeta Srivastava, Executive Director, Godavari Biorefineries Limited.

"It reflects the dedication of our teams and our aspiration to contribute meaningfully to global knowledge and innovation," she added.

Godavari Biorefineries has a global footprint, exporting to over 20 countries and maintaining strong collaborations with international research and development networks. Its clinical-stage biotech division, Sathgen Therapeutics, is leading the advancement of novel cancer and antiviral treatments.

With the lead molecule now under clinical evaluation and protected by global patents, the company is increasing its focus on translational research targeting critical global health challenges.

This development aligns with Godavari Biorefineries’ broader diversification into advanced scientific fields, complementing its existing leadership in ethanol, bio-based chemicals, and renewable materials derived from agricultural feedstocks.

Godavari Biorefineries is a pioneer in the renewable chemicals and biofuels sector.

Shares of Godavari Biorefineries were trading 0.81% lower at Rs 256.5 apiece on the BSE at around 10:02 AM.

Source: CNBC TV18

RISE OF BIO-BASED CHEMICALS: HYPE OR GAME-CHANGER?

Chemical Industry Outlook 2025, India Chemical News | Jul 27, 2025The latest BioE3 policy builds the framework for high-performance biomanufacturing to propel the development and production

.detail-para p { margin-bottom: 10px; } p { font-size: 16px; color: #000; line-height: 24px; }

DR. SANGEETA SRIVASTAVA Executive Director, Godavari Biorefineries Limited

The global and Indian bio-based chemicals market has enormous growth potential driven by a multitude of factors. The production of such chemicals depends on the availability of feedstock, and it is incumbent upon the stakeholders to manage all such components and ensure smooth processes to transition in a sustainable future.

COP 29 saw crucial strides in advancing climate action for developing countries but significant gaps remain. Issues like the scale of financing, the integrity of carbon markets, and concrete support for adaptation efforts require urgent attention and more decisive action. With Brazil hosting COP 30 this year, there is a critical opportunity to translate commitments into impactful solutions. As COP 30 approaches, the world will be watching to see whether this vital decade for climate action can deliver the results needed to protect the most vulnerable and secure a sustainable future for all.

The accelerated transformation towards a net zero circular economy is only feasible with a joint holistic approach to value chain collaboration. It became clear that alternative feedstocks, such as bio-based, CO2 -based and recycled feedstocks, are the key levers to enable this transformation.

The rise of bio-based chemicals is a game changer, and we do not have any other choice. We see slower growth towards adoption, but it is happening. We can adopt cleaner energy and recycling, but net zero will not be possible without de-fossilization. An integrated biorefinery is a step towards achieving this goal.

Defining Bio-based Chemicals

Such chemicals are usually produced through fermentation, enzymatic processes, chemical conversion, or biomass. They can be crops (including sugarcane, corn, soybeans), wood chips, lignin, algae, microbes, and organic waste.

Current State of the Market

With a global market size of over US $73 billion and a CAGR of 9.6% between 2024 and 2032, the popularity of bio-based chemicals is expected to increase further. Volatility in petrol and diesel prices, consumer preferences shifting to sustainable products, and depleting stock of non-renewables have fuelled the interest in these products. From the Indian perspective, the sector is also witnessing steady and robust growth with a strong CAGR and growth estimates.

Bio-based Chemicals and Biofuels

In the global economy, biotechnology has begun taking on a significant role. Bio-based chemicals and biofuels are connected through their shared feedstock use, standard processing techniques, and circular economy potential. However, the essential linkage is the role of integrated biorefineries in this process. For a biorefinery, it is necessary to be economical and to produce products at a price that customers would be keen to buy, which is the biggest challenge in the real world.

Each serves a different angle regarding ensuring sustainability across the value chain. Renewable fuels produce drastically less pollution compared to fossil fuels. At the same time, products developed from biochemicals help manage the waste generated from the process, help de-fossilization, and channel it into something productive.

Integrated Biorefinery Concept for Tomorrow

Integrated biorefinery processes are efficient for producing bio-based products and secondary energy carriers such as fuel, power, and heat, along with oil refineries. The pilot projects in India indicate that both conventional (biodiesel and ethanol) and advanced biofuels (of lignocellulosic origin) are yet to be produced profitably to create a sustainable market without implementing government policies and subsidies.

The integrated biorefinery concept enables the conversion of waste to high-value streams in economically attractive pathways by focusing on the key aspects: availability, affordability, sustainability, and productivity. As the world is going towards net zero, there should be a general (global) accepted policy of biogenic CO2 uptake calculation of different biomass crops. So, a biorefinery approach applied to different biomass crops will be more valued within climate policy.

Policies Pushing the Agenda

The Indian government, in a bid to accelerate the integrated bio-refinery agenda, has begun the Mission Integrated Bio-refineries Policy to also design innovative solutions in the sector. Ongoing bio-based innovations with enzymes would only foster and bolster these growth estimates.

In August 2024, the government launched the BioE3 Policy, which aims to channel the trickle-down impact of biotechnology on the economy, environment, and employment. This policy builds the framework for high-performance biomanufacturing, which will propel the development and production at the scale of bioproducts within the nation. With the nation's vast agricultural resources and burgeoning demand for fuel appropriately implemented, such a policy shift could radically change the economy.

The focus must be on strategies to manage the most potential source, i.e., agricultural residues. Some critical issues remain: deployment of existing technologies in agriculture, better agronomic and breeding technologies, proper supply chain, adequate policy framework, effective financing mechanism, and practical information dissemination. However, a policy like BioE3 could be instrumental in sparking sectors to tackle such obstacles.

Biofuels in India are crucial as they align with government initiatives such as Make in India, Swachh Bharat Abhiyan, Self-Reliant India, and skill development. They also offer opportunities to reduce imports, increase farmers' incomes, transform waste into wealth, and create employment.

Circular Economy and Biorefineries

In a broad future circular economy, biomass-originated chemicals will play a critical role. The products and processes to generate them from such materials are usually safe by design. Biorefinery systems will be vital to greater recycling and chemical and polymer production. To ensure a continuous fuel supply and to supplant the huge demand for emerging economies, economies have to be sustainable and circular - on one hand, manufacturing bio-based chemicals that have a wider use in products and bio-fuels that can reduce the dependency on fossil fuels. With both ranges of products, there can be a strong validation of the importance of bio-based products, possibly leading to production at scale.

Challenges Hindering Growth

Despite a promising scenario, there are some pertinent challenges that the industry needs to come together.

Feedstock Cost: Sugarcane molasses and other bio-based feedstocks compete with food production for land and resources. For countries with large populations like India, there are concerns that if the transition is rapid and sudden to bio-based feedstock cultivation, it could lead to price rise and adversely impact food security. Storing and transporting diverse feedstocks like cellulosic biomass could require substantial development and investment. In such cases, ensuring sustainable sourcing and proper resource utilization could be critical in elevating production and minimizing environmental impact.

Technology Constraints: Bio-based chemical manufacturers need to scale up rapidly to scale up rapidly and maintain cost-effectiveness. One way to do that would be through innovation and rapid advances. For production, efficient and affordable downstream processing is vital.

Management Issues: Transitioning to a bio-based future would require a skilled workforce with biotechnological experience. Proper waste management efforts are also essential in shoring up efficiencies in the bio-based production chain. These objectives would require close collaboration with multiple external stakeholders, government agencies, leading tech institutes, and private enterprises.

The Future of Chemicals is Green

Looking at the current state of affairs and the rise of biobased chemicals in the short term may seem like hype, but it is a game changer in the mid and long term. Countries and companies are sticking to their net zero and decarbonization goals. The global energy mix is observing a rapid transition to renewable fuels. While in its early stages, the market for bio-based chemicals in India shows genuine promise. Key stakeholders must come together to develop innovative alternatives that are marketable to the general public.

The sector needs better long-term planning and policies and technological solutions that are practical and effective in an actual life scenario. Lastly, while aim and vision should be high, the same can be done by taking small but concrete steps. It allows the ecosystem to grow while ensuring the penetration of fuel and technologies.

Click here to view the full content.

Source: Indian Chemical News

Will continue to contribute, innovate and co-create a green and sustainable ecosystem: Samir Somaiya, Chairman and Managing Director, Godavari Biorefineries

INDIA CHEMICAL NEWS | Jun 30, 2025We are in the bio-based specialty chemicals and continuously co-creating with customers and de-bottlenecking plants to meet the needs of customers

Samir Somaiya, Chairman and Managing Director, Godavari Biorefineries Limited

Godavari Biorefineries, one of the largest producers of ethanol and a pioneer in manufacturing ethanol-based chemicals in India, has a diversified product portfolio. The portfolio comprises of bio-based chemicals, sugar, rectified spirits, ethanol, other grades of alcohol and power. The company is the largest manufacturer of MPO worldwide and the fourth largest manufacturer of ethyl acetate in India, and the only company in India to produce bio ethyl acetate. Samir Somaiya, Chairman and Managing Director, Godavari Biorefineries, talks about the emerging market scenario as well as his company’s expansion plan…

Q. Biorefineries have gained significant attention in the quest for sustainable and renewable energy sources. How does Godavari Biorefineries contribute to the development and production of sustainable bio-based products?

A. The world continues to rely on fossil resources to meet its needs. If you take the example of energy, about 85 per cent of the world’s energy needs are met from coal, oil and gas. Countries such as Norway consume over 100, 000 kwhr per person, China consumes 30, 000 kwhr per capita and India is still at 8, 000 khwhr per capita. As India develops, its energy consumption will increase. It is important that this growth comes along with renewable resources so that we can grow and mitigate climate change at the same time, ensuring the sustainability of the planet.

Godavari Biorefineries is a company that is demonstrating this transition to the use of renewable resources. Godavari converts agricultural feedstock physically, chemically and biologically into food, fuel, chemicals and materials. Innovation is the cornerstone of our development. We have over 50 scientists constantly working with feedstocks, conversions and end-use applications. We partner with our customers to co-create solutions to aim and create renewable substitutes that have enhanced properties than the fossil intermediate that they substitute.

Finally, we are also working in the area of soil. Soil is the source of our feedstock. Fossil economies extract carbon, deplete the resource and then move to the next carbon source to extract the resource. Renewable economies extract carbon from the soil, deplete the same, but if farming is done right, then regenerate the soil. Renewable economies are circular, but this circularity must be worked on as we regenerate the resource. To improve agriculture, Godavari along with the research institute K. J. Somaiya Institute of Applied Agricultural Research (KIAAR) are working with our farmers to actively ensure soil is healthy for the immediate and the longer run.

Q. How is the favorable government policy accelerating the growth of bioenergy, ethanol and bio-based specialty chemical segments in the country?

A. India is rich in soil, sun and has millions of farmers. With these resources, we have to play to our strengths and have to transition from the oil economy to the soil economy. With this in mind, the Government of India is focusing on the green energy transition. Biofuels enhance energy security, mitigate climate change and help farmer income security

The Government set a target to achieve 20 per cent blending by 2030 and that was advanced to 2025, which we have achieved. The NITI Aayog is now examining to expand this beyond 20 per cent. When policies are well articulated, the ethanol industry, the farmers, the automakers, the equipment manufacturers, all come together to make this transition a reality.

Q. How is Godavari Biorefineries as a strong player in the sector contributing to the government of India's ambition?

A. Our business is into sugar, biofuels, co-generated electricity and bio-based chemicals. As the government is going for 20 per cent blending, Godavari is actively making ethanol from sugarcane juice and B Heavy-molasses. We expanded our capacity from what was 200, 000 liters per day in phases to 600, 000 litres per day. Now, we are adding a 200, 000 liters per day facility of grain/maize based ethanol, which will use maize and other grains to add to feedstock to supplement and increase capacity. It would be implemented in the second half of FY26.

Q. The biorefinery industry is constantly evolving and requires continuous innovation. What role does R& D play in the overall growth of the company?

A. There are three aspects of the research we do. First is the research on the soil. The carbon and soil regenerative practices that will make sure that we have the carbon which is required to be transformed. The fossil economy is extractive, and biorefining can also be regenerative. We can always extract from the soil but if we do it wrong, it can get poor in carbon. But if we do it right, the soil has the ability to regenerate.

The second area of research is the conversion of this biomass into food, fuel and biochemicals. We have a lot of scientists working on physical, chemical and biological transformation.

And the last aspect is where we work with customers to co-create with them. They also have their transitional journeys and are looking at products that we make including drop-ins or could be an applicational substitute with enhanced properties.

Similarly, when I talk about regenerative farming, we have to co-create value with farmers. It is an emphasis on renewables, emphasis on co-creating work with either the farmers or customers, and the emphasis on innovative science whether physical, chemical or biological.

|

Blurb: “As the government is going for 20 per cent blending, Godavari is actively making ethanol from sugarcane juice and B-molasses. We expanded our capacity from what was 200, 000 liters per day in phases to 600, 000 litres per day. We are now adding a grain/maize based ethanol facility to further add 200, 000 liters per day…” |

Q. Godavari Biorefineries has a strong focus on sugarcane based products. How does the company ensure sustainable sourcing practices and support for the local agriculture community?

A. We are working with our farmers on regenerative agriculture which is good for both short term and long term. We have a separate independent, agriculture research institute, KIAAR, where a lot of research is done in combination of drip farming, intercropping with sugarcane, looking at regenerative practices and remote sensing. This involves the whole range of traditional with modern science, looking at sustainability in the short and the long run and to help farmers improve crop yield and income.

Q. Can you highlight any recent advancements or technological innovations that Godavari primarily implemented to enhance its biorefinery operation?

A. We are advancing three aspects. One is we are going into a maize/grain based ethanol facility to supplement the feedstock from sugarcane and to mitigate climate risk. The second aspect is that we are in the bio-based specialty chemicals and continuously co-creating value added products with customers. Whether that is the need for a product which has properties in the substituting fossil or substitutes purely as a drop-in, we are working on new chemicals continuously. We will come with new products or enhance capacities as we go forward.

Q. Sustainability has become a key priority for businesses worldwide. How does Godavari Biorefineries integrate sustainable practices into its overall operations, including resource consumption and emission reduction?

A. We are fundamentally sustainable as much of our feedstock is biogenic carbon. Our energy also primarily comes from biogenic carbon - bagasse is our main energy source. We do use some amount of coal, but overall our energy matrix, the carbon we consume for energy or for chemical operations, the majority of that is biogenic carbon.

|

“We are working to co-create value with our farmers and our customers, using research and innovation as our strong foundation for growth.” |

Q. In addition to bioethanol, what other bio-based products does Godavari produce?

A. We make a host of bio-based chemicals that find applications in a variety of fields including skin-care, cosmetics, agrochemicals, paints, coats, and pharmaceutical intermediates. Our scientists are continuously working, and co-creating with customers to expand the bouquet of products available to them.

Q. What are the key strategic priorities and growth plans for the Godavari Biorefineries in the segments that you operate?

A. Climate change has to be addressed and also in terms of transition to green energy, Godavari will continue to contribute and play its role. In this direction, there could be three sets of customers. The first set of customers are an end use customer who may want to buy a product that comes from natural or renewable feedstock. Another set of customers may be looking at a green substitute for an existing fossil product that has enhanced properties. The third would just be looking at reducing the chemical footprint.

Our customers are in either one category or in two or all three of the above. We are seeing the growing interest among our chemicals in this transition. In summary, there is a wider interest in the green transition in chemicals. In India, there is an articulated policy in the transition to renewable energy. We are actively participating in both these transitions.

We are living in exciting times. We have to realize that each one of us, individually and as institutions, have to look at sustainability in our processes and co-creating with customers and also co-creating value with the supply chain. We have to create value and look at research as a bedrock of that value. That's how I look at it and Godavari follows this process very sincerely.

Source: Indian Chemical News

Godavari Biorefineries Q4 FY25 profit rises; 200 KLPD grain distillery expected to be commissioned in Q4 FY26

chinimandi.com | May 26, 2025Godavari Biorefineries Ltd., one of the larger producers of ethanol and a pioneer in manufacturing ethanol-based chemicals in India, announced its Audited Financial Results for the quarter ended on March 31, 2025.

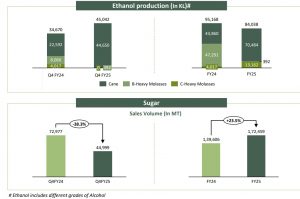

During Q4 FY25, GBL reported Revenue from Operations at Rs. 579.5 crore as compared to Rs. 615.2 crore in Q4 FY24. The company reported PAT of Rs. 96.4 crore in Q4 FY25 as compared to Rs. 65.2 crore in Q4 FY24. During the quarter, Ethanol production stood higher at 45,042 KL as compared to 34,670 KL in Q4 FY24.

For the Financial Year ended March 31, 2025, GBL posted Revenue from Operations higher at Rs.1, 870.3 crore as compared to Rs. 1,686.7 crore. Ethanol production during the year was at 84,038 KL as compared to 95,168 KL.

Commenting on the Results, Samir Somaiya, CMD said, “FY25 was a defining year for Godavari Biorefineries, showcasing our agility, disciplined execution, and strategic progress. Our Bio-based Chemicals segment delivered over 2x growth in EBITDA, propelled by our shift toward high-value, sustainable solutions and enhanced operational efficiencies. We also achieved a record cane crushing of 24.65 lakh tonnes for sugar season 2024-25 at our Sameerwadi facility. The restoration of the ethanol blending programme using sugarcane juice enabled us to better utilize our ethanol capacity during the crushing season.”

“Looking ahead, our 200 KLPD grain/maize distillery is progressing as planned and is expected to be commissioned in Q4 FY26. We are also exploring multi-feedstock options for greater flexibility, while undertaking debottlenecking and expansion initiatives focused on specialty products. FY25 has laid a solid foundation for future growth, and we remain committed to delivering value through innovation, sustainability, and disciplined growth,” he further added.

Source: chinimandi.com

How Jivana Achieved 5x Growth by Championing Chemical-Free Staples

indianretailer.com | Mar 25, 2025India's FMCG landscape is undergoing a massive transformation, with consumers increasingly prioritizing purity, health, and transparency in their everyday purchases. Amid this evolving market, Jivana, the B2C brand of Godavari Biorefineries Limited under the Somaiya Group, has carved a distinct niche. Founded with a clear mission to offer pure, unadulterated staples to Indian households, Jivana has swiftly gained recognition for its ethical sourcing, sustainable practices, and unwavering commitment to quality. The brand’s dedication to delivering chemical-free, minimally processed products has resonated with health-conscious consumers seeking authenticity and transparency in their food choices.

This FMCG brand has strategically aligned itself with five major trends shaping the Indian market — the shift to packaged products, heightened hygiene and safety concerns, demand for transparency and assurance, the growing influence of social media, and an increasing preference for health-focused offerings. By embracing these trends, Jivana is not only meeting consumer expectations but also redefining standards in the packaged staples segment.

The fast-moving consumer goods (FMCG) sector in India is experiencing a monumental shift. According to a report by Custom Market Insights, India's FMCG Market is expected to record a CAGR of 21.8 percent from 2025 to 2034. In 2025, the market size is projected to reach a valuation of $211 billion. By 2034, the valuation is anticipated to reach $1178 billion.

Swati Shukla, Head - Food and Farms (Jivana) at Godavari Biorefineries Limited said, “The Indian FMCG market is rapidly shifting towards packaged products driven by hygiene, health consciousness, and consumer awareness. At Jivana, we align with this trend by ensuring purity, adopting hygienic packaging, and empowering consumers to verify quality themselves.”

Competing in a Crowded Market Despite intense competition in the FMCG sector, Jivana’s adherence to quality and transparency gives it a unique edge. The brand refuses to cut corners, even when cost savings are possible. For instance, unlike many competitors who add sugar or preservatives to extend jaggery’s shelf life, it remains committed to chemical-free processing, prioritizing consumer health over profit margins.

“Jivana stands out through ethical sourcing, unwavering quality, and a deep-rooted commitment to sustainability — practices we have upheld long before they became industry buzzwords. We never take shortcuts, ensuring purity in every product while empowering consumers with awareness. This dedication has fueled our growth and earned the trust of those who value authenticity,” Swati stated.In the past three years, Jivana’s revenue has grown fivefold, crossing the Rs 100 crore mark. The brand’s strategic focus on expanding both geographically and across retail channels is expected to sustain this growth trajectory.

In the past three years, Jivana’s revenue has grown fivefold, crossing the Rs 100 crore mark. The brand’s strategic focus on expanding both geographically and across retail channels is expected to sustain this growth trajectory.

Sales Distribution Across Channels

Jivana’s sales are divided into two primary categories: General Trade (GT) and a combined segment of modern trade, e-commerce, and quick commerce. Currently, 70 percent of its sales come from general trade, which includes Kirana stores, mom-and-pop shops, and local retailers. The remaining 30 percent is driven by modern trade platforms, e-commerce sites, and quick commerce services, reflecting a growing consumer shift toward organized retail.

Swati emphasized, “We aim to expand Jivana’s reach across our existing seven states, not just in Tier I cities but also in Tier II and III towns. Consumers in smaller cities are increasingly health-conscious, and we want to make Jivana products available to them through multiple channels.”

Jivana products are already available on leading platforms like D-Mart, Reliance, Big Basket, Swiggy, Zepto, and Blinkit. The brand is further strengthening its presence across all major retail touchpoints to ensure seamless accessibility.

Consumer Trust Through Transparency

Indian consumers are becoming increasingly aware of the hygiene and safety advantages of packaged products. While loose staples once dominated the market, packaged sugar and jaggery are now witnessing higher demand. Jivana has been a pioneer in this shift by emphasizing hygienic packaging and untouched-by-hand processing.

“Commerce today is not just about selling; it’s about building trust, adapting to evolving consumer behaviors, and leveraging digital platforms to create seamless experiences. Brands that embrace innovation and transparency will lead the future of retail,” Swati noted.

Breaking the Mold

Jivana’s product innovation reflects its dedication to consumer health. One of its flagship products, sulphur-free refined white sugar, offers 100 percent purity by eliminating harmful traces of sulphur typically found in conventional sugar. Additionally, its natural brown sugar is enriched with essential minerals like magnesium and calcium, catering to health-conscious consumers.

Swati highlighted, “If your jaggery is filled with chemicals, you might as well have plain sugar. Our jaggery, purified using ladyfinger extract with no chemicals or added sugar, stands out as a healthier alternative. Naturally dark brown and rich in minerals, it enhances both flavor and well-being.”

Sustainable Supply Chain

Sustainability and ethical sourcing are integral to Jivana’s operations. Collaborating with over 35,000 farmers in North Karnataka, the brand ensures fair wages and promotes sustainable farming practices. Through its research arm, K. J. Somaiya Institute of Applied Agricultural Research (KIAAR), Jivana provides farmers with guidance on soil health optimization and reducing chemical use.

“Jivana’s supply chain is built for efficiency and freshness, from our large sugar mill in North Karnataka to our extensive distributor network. With real-time inventory tracking and optimized logistics, we ensure that pure, high-quality products reach retailers and consumers seamlessly,” Swati explained.

Future Plans

Jivana plans to deepen its presence within its existing seven states—Maharashtra, Gujarat, Rajasthan, Madhya Pradesh, Karnataka, Andhra Pradesh, and Telangana—by expanding into Tier II and III cities. Its goal is to increase product accessibility across all retail channels, including modern trade, general trade, and e-commerce.

“For now, we’re focused on strengthening our presence in the current markets. Once we achieve saturation, we will explore further geographical expansion,” Swati concluded.

Jivana is also eyeing international expansion, targeting regions with a significant Indian diaspora where authentic Indian staples like jaggery and spices are in high demand. With its unwavering commitment to quality and sustainability, Jivana is well-positioned to become a household name in both domestic and global markets.

Source: indianretailer.com

Godavari Biorefineries Limited Announces Investment in a New Corn/Grain-Based Distillery to Enhance Ethanol Production

Dec 16, 2024(Strategic Investment of approximately ₹130 Crore to Boost Ethanol Capacity with Dual-Feedstock Flexibility, Aligning with India’s Green Energy Goals.)

Mumbai, December 16, 2024: Godavari Biorefineries Limited (GBL) (BSE: Script Code 544279 | NSE: GODAVARIB), a pioneer in renewable chemicals and biofuels, has announced an investment in corn/grain-based ethanol to further strengthen its ethanol production capabilities. The company plans to invest approximately ₹130 crore in a new 200 KLPD corn/grain-based distillery as part of its existing operations, enhancing flexibility through dual-feedstock capability. The company reported a 25% Y-O-Y increase in revenue growth in H1FY25, demonstrating its operational strength and focus on sustainable growth.

Key Highlights of the Investment:

- Proposed Capacity: 200 KLPD corn/grain-based distillery.

- Investment Required: Approximately ₹130 crore.

- Mode of Finance: Internal accruals and debt.

- Commissioning Timeline: Q4 FY 2026.

This strategic move aligns with GBL’s long-term vision of supporting India’s transition to green energy while ensuring resilience against climate-induced risks. The new facility will offer operational fungibility, enabling the use of alternative feedstocks such as maize to mitigate disruptions caused by factors like poor monsoons and policy changes.

Mr. Samir Somaiya, Chairman and Managing Director of Godavari Biorefineries, said, “We are investing in new corn/grain-based ethanol production to complement our existing sugarcane-based operations. This will give us a dual-feedstock capability and will ensure more resilient ethanol production, even during climate-related disruptions, and position us to meet the growing demand under India’s ethanol blending program. This expansion will help us maintain production stability and contribute to India’s energy security goals.”

The expansion comes at a pivotal time as India’s ethanol demand rises, driven by its ambitious blending targets and increasing energy requirements for mobility. By leveraging dual-feedstock technology, GBL aims to strengthen its market position and ensure consistent growth.

About Godavari Biorefineries Limited (GBL):

Godavari Biorefineries Limited (BSE: Script Code 544279 | NSE: GODAVARIB), flagship company of Somaiya Group, is a leading integrated biorefinery specializing in bio-based chemicals, ethanol, and sugar production. The company operates cutting-edge facilities in Sakarwadi, Maharashtra, and Sameerwadi, Karnataka, and houses advanced R&D facilities in Mumbai and plant locations. Listed on the BSE Limited (BSE) and the National Stock Exchange of India Limited (NSE), GBL has a legacy of innovation and a commitment to sustainability, driving progress in renewable energy and green chemistry. For more information about Godavari Biorefineries, please visit www.godavaribiorefineries.com.

Looking to add specialty chemicals to our portfolio: Samir S. Somaiya, Chairman and Managing Director, Godavari Biorefineries

INDIA CHEMICAL NEWS | Jun 14, 2024How does Godavari Biorefineries contribute to development and production of sustainable bio based products?

Biorefinery means conversion of an agricultural biomass into food, energy, biofuels, compressed biogas and even electricity. It also means conversion of biomass into chemicals and materials.

Godavari has always been pioneering the conversion of biomass into these products. In the 1940s, it was sugarcane cultivation and sugar production. In the 1950s, it was the conversion of molasses to Ethanol. In the 1960s, we started small in making chemicals from Ethanol. In the 1990s, we were one of six projects in the country to be chosen by USAID to show how climate change can be mitigated by greenhouse gas mitigation projects. We were awarded a grant from the USAID to demonstrate the making of surplus power from bagasse. In the recent past, we were among the first companies to demonstrate the use of sugarcane juice/syrup as a feedstock for making Ethanol in India.

The company received a Rs. 15 crore grant from the Department of Science and Technology. Can you please share the details?

In biorefining, there is a need to have access to biomass and the question that we are trying to ask is how it can be done with reasonable cost which refers to Capex and Opex. Sugarcane processing companies save bagasse (8-9% on cane) and so have abundant feedstocks. Secondly, the distilleries make Ethanol seasonally. They have idle capacity. The idea is to use this idle capacity with a bolt-on facility to make Ethanol from bagasse with the addition of bagasse pre-treatment. So, there is no need to create a new facility all the way from biomass pre-treatment, collection, pretreatment, fermentation and purification. We just need the treatment of the biomass to convert to sugar for fermentation. This is the whole concept and we want to try and pioneer and see how it is possible.

When do you see this finally shaping up?

To be able to demonstrate this in a reasonable manner, a policy environment needs to be in place. The creation of PPAs (Power Purchase Agreements) enabled sugar mills to install power plants. Similarly, a mandate for Ethanol blending with a declared price for juice/syrup helped create that investment). Similarly, a policy framework for 2G Ethanol will help spur investment. The moment we create a framework and a market, only will then one allow or incubate innovation to make it happen.

How favourable government policy is accelerating growth of bioenergy, Ethanol and bio-based speciality chemicals? At the G20 Summit, many nations came together to create an association for Ethanol. How will this help companies like you in the long run?

One is the Indian context and the other is the global context. In India, there is a need to have energy security that supplements and substitutes the energy that the country imports from overseas. India is rich in biomass and the policies have to encourage the conversion of biomass. The government mandates Ethanol blending and is targeting 20% blending in the next couple of years. Similarly, there is a mandate that is going to come for Compressed Biogas (CBG).

India has to look at it also from an energy security as well as climate change angle. India is committed to achieve net zero by 2070. Moreover, India has a lot of small farmers and their income security is necessary and this is helped by a dual product from sugarcane if it can go to sugar and Ethanol. The infamous sugar cycle that used to have big surpluses and deficits gets insulated because these surpluses can go into the Ethanol.

Are you also looking at focusing on CBG? How many plants are you planning to set up?

We will certainly do that and at the moment we are exploring the setting up of a CBG plant.

How is Godavari contributing to the Government of India's ambition on these fronts?

As mentioned, we were the first off the post when the policy of Ethanol from sugar cane juicer syrup was announced.

We increased our Ethanol capacity from 200,000 to 320,000 litres per day. Later, we increased the capacity from 320,000 to 400,000 litres per day and now we have gone from 400,000 to 600,000 litres per day. We are very active in increasing the Ethanol programme. We are looking at grain and maize as a feedstock in the coming future to make this a multi feedstock facility. We are also looking at CBG in the future.

You are setting up a grain-based Ethanol project. What is the current status of the project and when are you planning to complete it?

We have already received necessary approval from the government. It will help us as a dual feedstock and lead to risk mitigation. As it is a short-term crop, in case there is a monsoon failure, it also gives us a twin feedstock to run our facilities, enhancing capacity utilization of the distillery. Grain-based plant is being planned for two lakh litres per day.

What are your plans for bio-based chemicals?

In addition to making our Ethanol facility, multiple feedstock facilities, we are also looking to add Specialty Chemicals to our portfolio. We believe that the use of bio-based biomass to make chemicals, and in particular Speciality Chemicals, is going to be also an area of future development.

There is a big thing of looking at biogenic carbon as a feedstock compared to fossil carbon. This is encouraged by either boardroom commitments, regulations or customer preferences. So, Godavari is continuing to work to make Specialty Chemicals that may find application in Pharma Intermediates, Agro Intermediates or in Coatings, Paints and a wide variety of chemical applications.

We are working with customers closely to see whether we make a drop-in product or it could be a green substitute with slightly better properties so that the substitution may create a better category of product. Traditionally, these things don't happen overnight. You are not substituting a fossil commodity with a green commodity and that would not work because it has a very different economic base. It takes time to work with customers. Godavari is definitely looking to work on bringing in new products in the next financial year.

How does biorefinery foster a culture of innovation and how will research and development play in its growth?

We look at research from four points of view. We look at research on the farm and agriculture site because ultimately biomass is grown on the farm. We have laboratories in Mumbai for lab work. We have pilot plants and research facilities with slightly larger lab facilities in the plants and Anally we have some pilot plants where we can do a semi-commercial business before we go to commercial. So, we have a comprehensive culture of innovation. We have many Scientists and Engineers working with us and we also collaborate with people outside.

What sort of approach to waste management and utilization of waste streams in the operations that you do?

I think the first idea is to think of waste as wealth and see how one can find use in all the waste streams that we have. Recycling brings value from it. Around 50-60 years ago, molasses itself was a waste stream and it became Ethanol. Bagasse was a waste stream and it became electricity. We have various streams today. Now, we are looking at finding ways to extract potash out of the ash of the incineration boilers in a distillery. We are making bricks from some of our other ash. We are also working very seriously on recycling streams.

How does Godavari ensure sustainable sourcing practices and support the local agriculture community?

We are now focusing on research for sustainable sourcing. We often see depletion of oil reserves, gas reserves, trees or coal but we don't observe the depletion of the soil carbon. Ultimately, it is the soil carbon that will convert to biomass, which we can either use for food or energy. The depletion of soil carbon depletes will reduce yields of these products. At the same time, if we can increase this soil carbon, we are going to improve the yields and sequester a lot of carbon in the atmosphere. We are executing a big project on this with Somaiya Vidyavihar University. Agriculture researchers are working on this with a lot of farmers and trying to see whether we can do this on a large scale.

How do you see Godavari Refineries integrating sustainable practices into its overall operations, including resource consumption and emission reduction?

Sustainability is part of our DNA. When we work with farmers to improve soil carbon, we also ask them if they can intercrop with nitrogen Axing kinds of crops such as soya to reduce the use of chemical fertilizers. We are working with them to use traditional agro-ecological practices. The success of this will automatically start sequestering more soil carbon and reduce Scope 3 emissions. Secondly, once CBG is in place, one can also work with tractor manufacturers to start using tractors on CBG. This is futuristic thinking but it is doable.

We are constantly thinking of how we work on energy efficiencies to further reduce Scope 2. We can produce more electricity from the same biomass. When we are continuously innovating to make products from biogenic carbon, we will continue to reduce Scope 3 as we supply.

For us, sustainability is not just environmental but also social, and we keep educating farmers about soil carbon. Hence, it is the wider definition of sustainability that we work on. When we are able to produce a product that may have a better profile for customers, you have actually achieved a complete win. We are also getting certifications from global bodies such as Bonsucro.

When are you planning to achieve net carbon zero?

We published our first sustainability report and we will articulate a strategy going forward. We want to build our strategy of converting biomass into biofuels, foods, sugar, electricity and more a whole range of new chemicals. This is not a 12 month exercise but a continuous exercise. We will continue to innovate and the effect will be seen in quarters and also in years.

Your thoughts on the future of the biofuel programme?

The Prime Minister at the 90th anniversary of the RBI mentioned about the Ethanol programme. He gave an interview in which he talked about the Ethanol Blending Programme and it finds mention in the BJP manifesto. I believe if India has to maintain its path to net zero and maintain its energy security in the light of current geopolitics, the Biofuel programme will grow.

Does the company plan to go for the IPO in this financial year?

We are certainly looking at Aling DRHP this year.

We are looking at grain and maize as a feedstock in the coming future to make this a multi feedstock facility.

Source: India Chemical News

Inauguration of Specialty Chemicals Plant at Sakarwadi by Padma Vibhushan Prof. M. M. Sharma and Hon'ble Mr. Bart De Jong, Consul General of Netherlands in Mumbai

May 24, 2024

We are delighted to announce the grand inauguration of our state-of-the-art Specialty Chemicals Plant at Sakarwadi, Maharashtra. The ceremony was honored by the esteemed presence of Padma Vibhushan Prof. M. M. Sharma and Hon'ble Mr. Bart De Jong, Consul General of the Netherlands in Mumbai, along with other distinguished guests.

The inauguration marks a significant milestone in our journey towards innovation and excellence in the production of specialty chemicals. This advanced facility, equipped with cutting-edge technology, underscores our commitment to the highest standards of safety and environmental sustainability.

Padma Vibhushan Prof. M. M. Sharma, a luminary in the field of chemical engineering, performed the ribbon-cutting ceremony and delivered an inspiring address. He highlighted the critical role of research and development in the chemical industry and praised our efforts in establishing a plant that represents the future of specialty chemicals manufacturing.

The event was further distinguished by the presence of Hon'ble Mr. Bart De Jong, Consul General of the Netherlands in Mumbai. In his address, Mr. De Jong emphasized the importance of international cooperation in advancing technological and industrial growth.